Software

Computer Integrated Documentation Pro V5

Operating system has never been so simple and user-friendly!

With our powerful CID software you can control up to 32 plants and equipment, programming cycles and document your data. You will receive all important device parameters at a glance, can comfortably program your cycles and analyze your measurement results. Also, send event-triggered e-mails the CID software, so you are always informed about the functioning of your equipment.

- All important equipment data at a glance

- UComprehensive communications possibilities

- Display of all tests in progress in your laboratory for efficient test planning

- Convenient input of test cycles

- Clear evaluation of test results

- Communication to unit configurable via RS 232, RS 485 or network

- Online monitoring feature for other computers in network

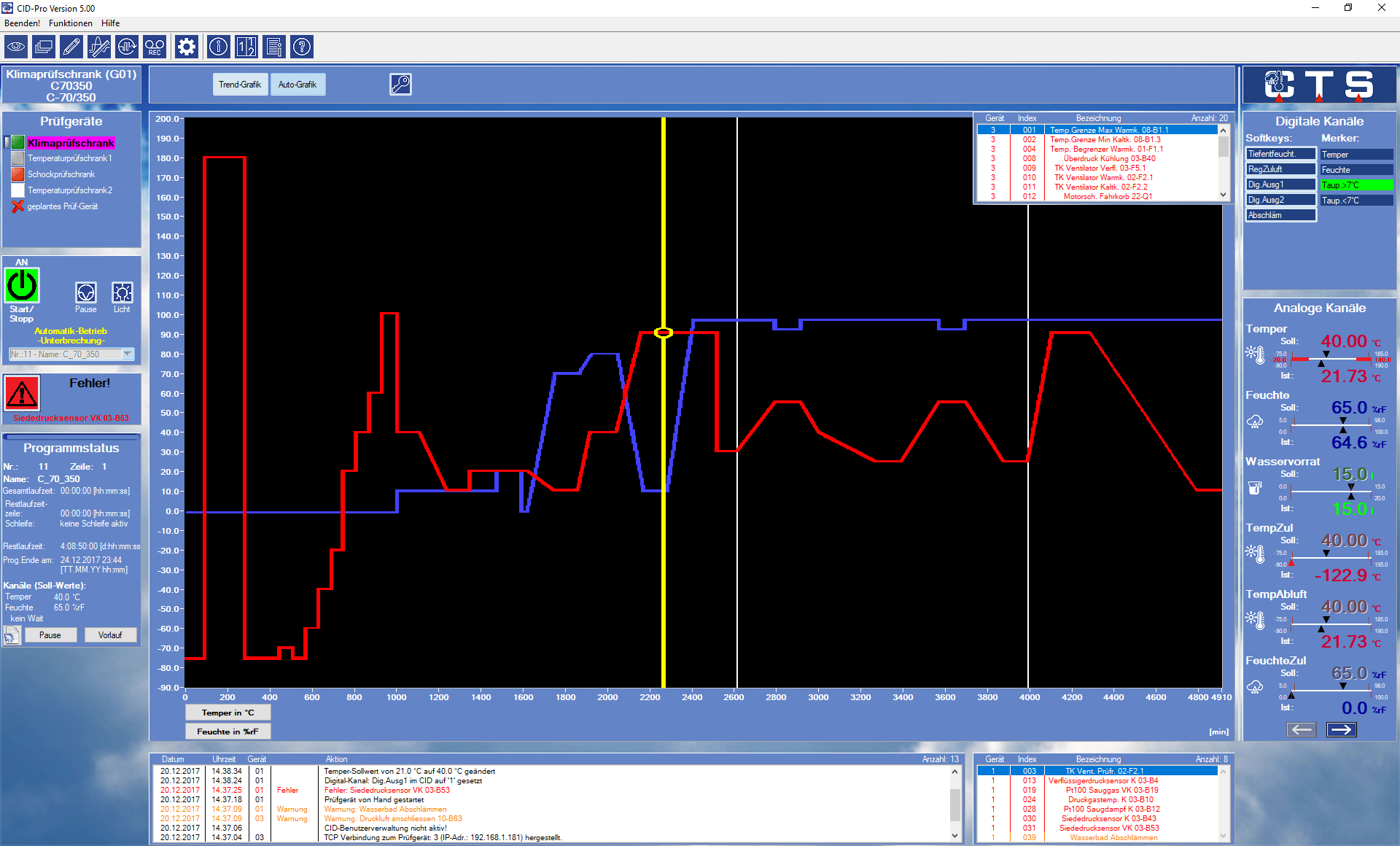

Status Overview

The new CID-Pro V5 is impressive for its ease and self-explanatory operation. All functions are menu driven and shown as symbols. In addition, substantial amounts of information from the unit are displayed and can be partially edited.

- Displays all connected units (chamber names and status).

- Displays all analogue and digital channels for any selected unit.

- Displays status information for the selected unit (automatic or manual operation, error reports).

- Dynamic contextual screen set up – elimination of unnecessary or confusing elements.

- Displays all functions via symbols and menu bars. All symbols also contain a tool text-description.

- Short but significant reports listing for all units.

- The chamber name is easily editable to meet requirements.

- Language can be changed during running time to either German, English or Czech.

- Help as PDF format.

- Supporting operating systems Microsoft Windows 11, 10, 8, 7, Vista, XP, 2000 Service Pack 3

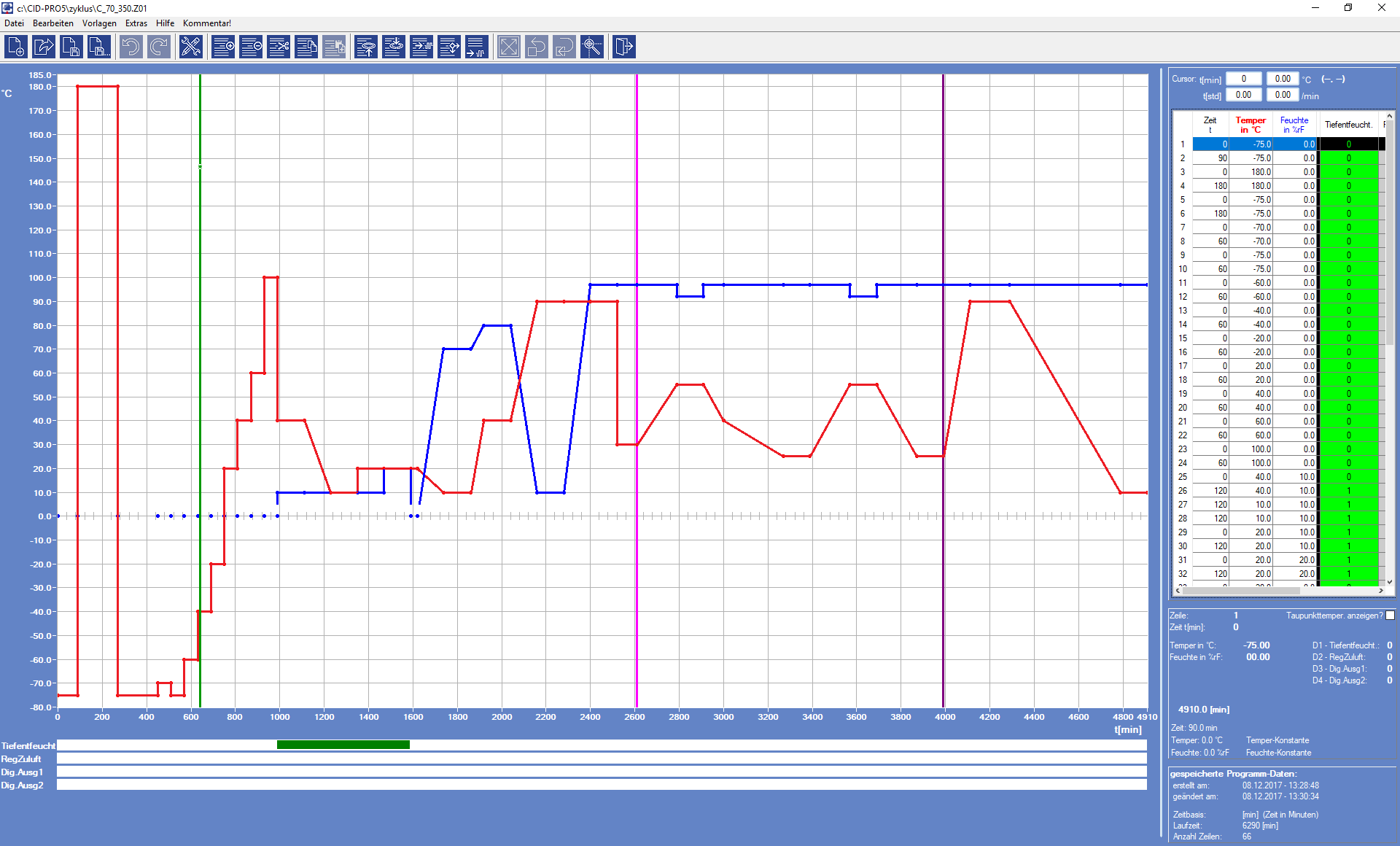

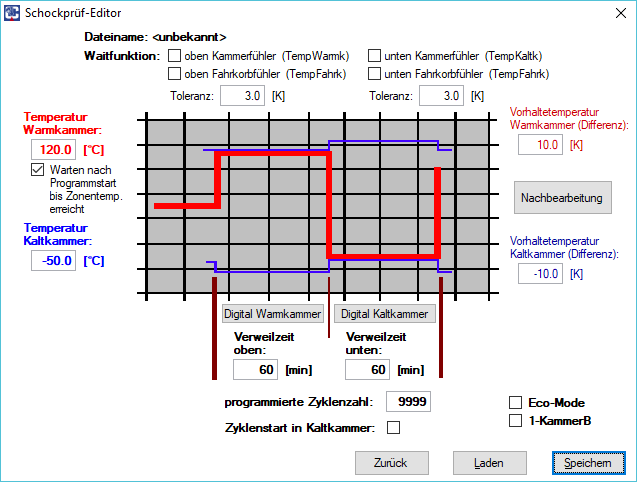

Editor

Create your test cycle programs simply and easily. The new extended CID-Pro V5-Editor has many helpful functions making its use even easier, e.g. copy and past lines or line-blocks, calculate gradients exactly or save programs as template-modules.

- Create, change or delete the test cycle programs.

- Define value lines, loops, conditional jumps or subprograms in the test program.

- Set the time base of a program: Seconds, minutes or hours.

- Zoom a specific area to set a value more accurately.

- Zoom to 20 levels.

- Display all functions via symbols and menu bars. All symbols contain a tool text-description.

- Detailed information of all channel values for the selected lines.

- Copy lines or whole blocks and paste them back again.

- Create or shift a point in the graphics with double click on the new point.

- Loads the last test program opened.

- Save programs as templates that can be pasted back as modules.

- Define a fixed gradient for a point (e.g. -5K/min cooling or 5K/min heating.)

- PDF printout.

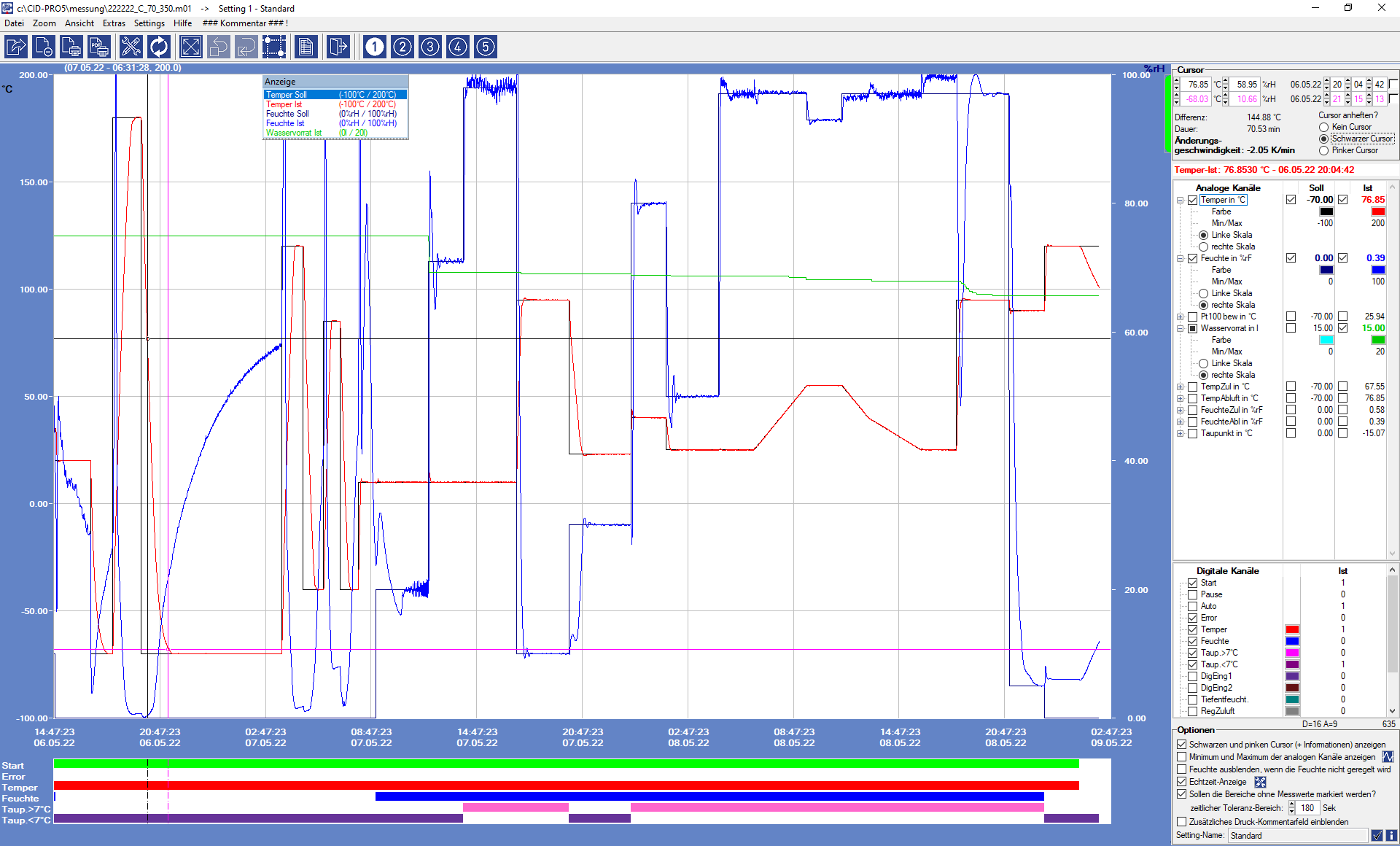

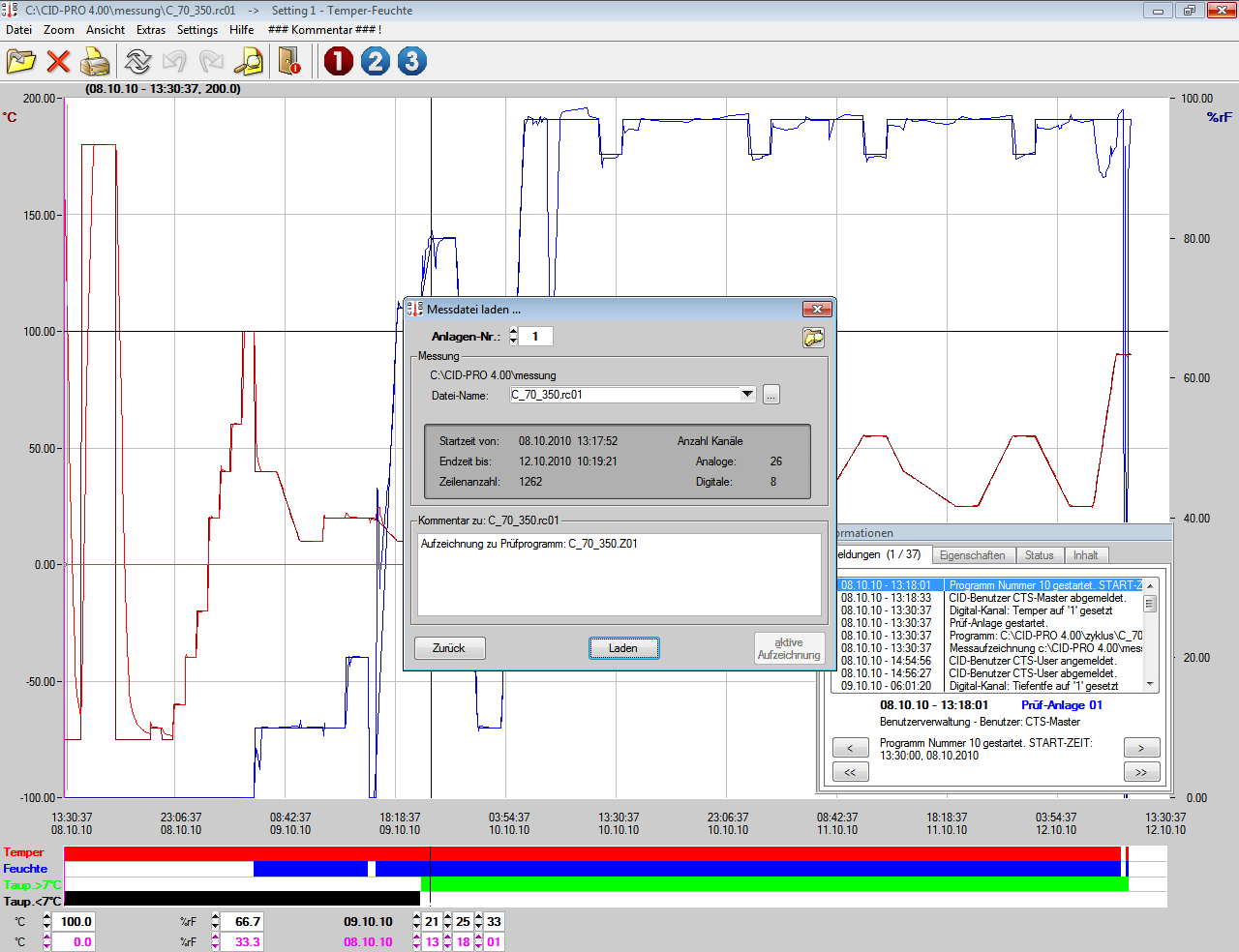

Graphical measurement data evaluation

A record of the test cycle program can be created storing all analogue and digital channels. This data can be evaluated and the results imported into Microsoft® Excel if required.

- Display complete measurement results.

- Easy selection of analogue and digital channels at runtime using the tables on the right, as well as other options such as range and colour.

- Zoom function with scroll bars: Simply zoom in and use the horizontal and vertical scroll bars to shift in time in the X direction and in the Y direction. If you have zoomed in, the graphic can be moved completely by holding down the Ctrl key and the left mouse button. An overview window is now also available in which the section can be moved.

- One of the two cursors can be "pinned" to one of the analogue channels, i.e. it can no longer be placed freely, but is connected to the nearest set or actual channel. If this function is activated, the internal memory is accessed directly and all measured values at the selected time are output in the table as set and actual values.

- Standard-configuration for the display of analogue and digital channels is selectable: The first 4 analogue and 4 digital channels have standard-set-actual-colours.

- Extended search for measuring files.

- Measured files for the same configurations can be combined.

- Optimized Microsoft® Excel export function with user changeable options.

- Show measurement results in a table (complete or within cursor positions).

- PDF printout resp. logging

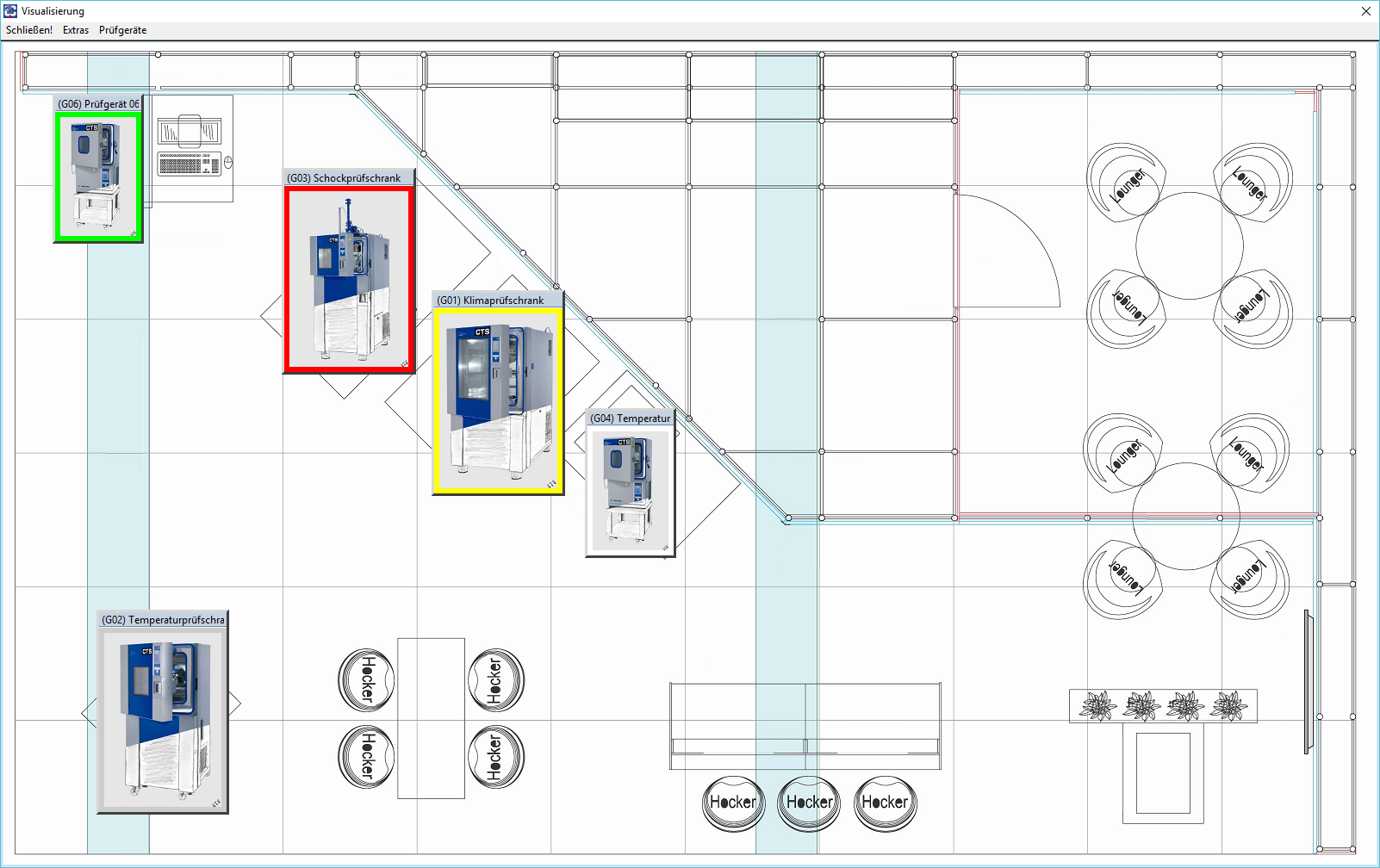

Visualising

- With the new menus, there is the option to visually display the layout of your units with site layout background photos and pictures of the individual setups. Units can be configured with user-defined sizes, position and appearance.

- Key information is displayed when the cursor is moved over a chamber.

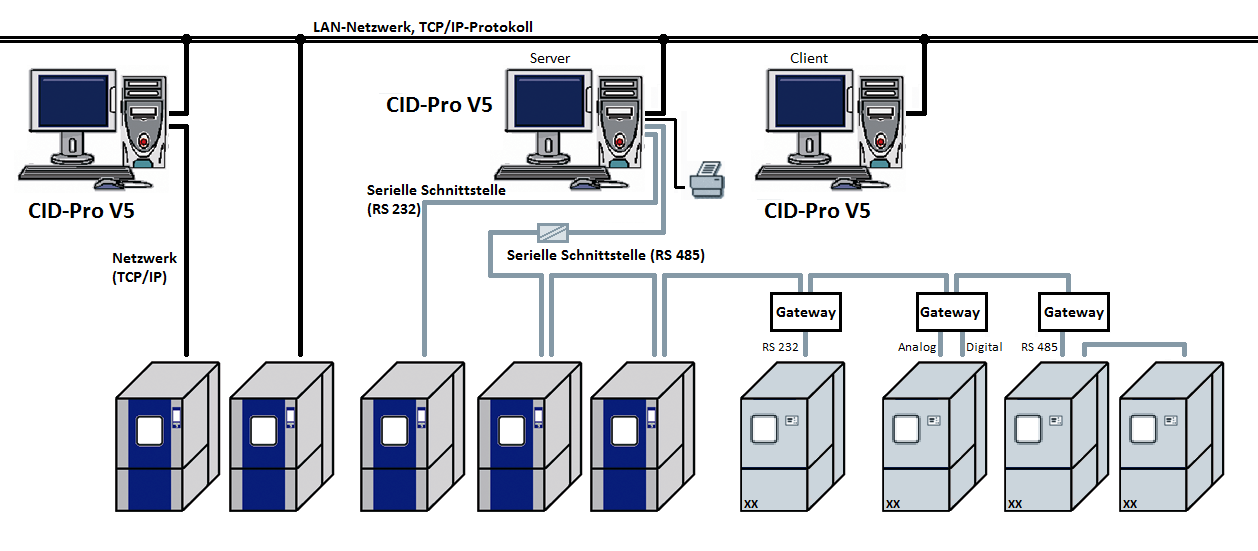

Networking

- Communication to the setup is freely configurable through RS232, RS485 or a network. Additionally, an online monitoring function is provided for other computers on the network.

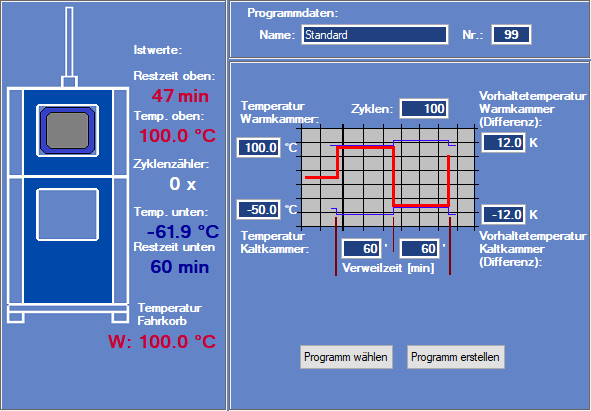

Special menus for Temperature Shock-Test-Cabinets

- A particularly clear display of the configuration with the special shock-test menu. The heating chamber, lower cold chamber or lift cage temperature - all information at a glance.

- With the shock test editor, standard shock test programs can be easily created.

Computer Integrated Documentation Pro V4.01 - QV

Qualified Software System

The CID-Pro 4.01 QV software has been specially designed for users who have to work according to the "Good Manufacturing Practice" (GMP) or GLP (Good Laboratory Practice) regulations, such as those specified by the EU in the EU-GMP -Guide or the FDA in 21 CFR Part 210/211. The same applies to users who use the software in connection with the manufacture of medical products / medical devices and are therefore only allowed to use computer-aided systems that have been proven to be validated / qualified.

Drugs or medical devices must be manufactured using validated processes and appropriate equipment to ensure patient safety, product quality and data integrity at all times. If climatic test chambers are used in this context, their control and the processing of the recorded data is to be regarded as critical in terms of the criteria of patient safety, product quality and data integrity. This classification means that all devices, machines and systems involved must be validated.

The validation of the computer-aided system CID-Pro 4.01 QV follows the system concept proposed by PIC/S and the validation approach of GAMP 5 1: The validation approach pursued here brings in those validation activities that can be effectively supported by the system supplier, such as the system specification, test planning (IQ and OQ) and the training concept. The creation of the SOPs required for operation and administration can be based on the QV user manual, the technical specifications and the notes on monitoring and disaster recovery.

1 GAMP 5 - A risk-based approach to compliant GxP computerized systems, 2008

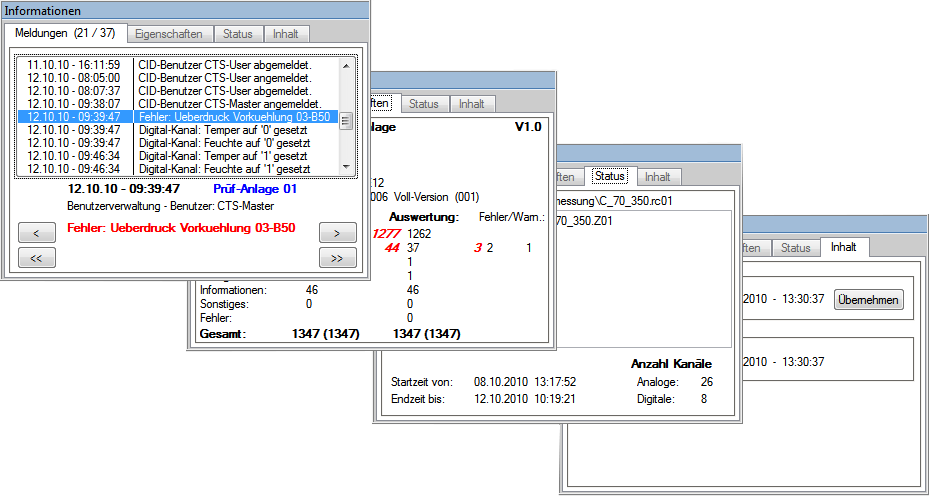

Excerpt from CID-Pro 4.01.006 - QV Representation of an RC measurement file with additional information such as messages, properties, status and content.

Overview of the CID-Pro 4.01 QV version

- IQ Installation Qualification

(System, Software Installation, User administration, system networking, data security)

- OQ Operation Qualification

(Test instructions, functional tests)

Overview of the CID-Pro 4.01 QV version

Important:

colored identification of error and warning messages!

System requirements

- Microsoft Windows 11, 10, 8, 7, Vista, XP, 2000 Service Pack 3 or later

- Free serial or Ethernet interface

- Free USB port for a hardware key (dongle)