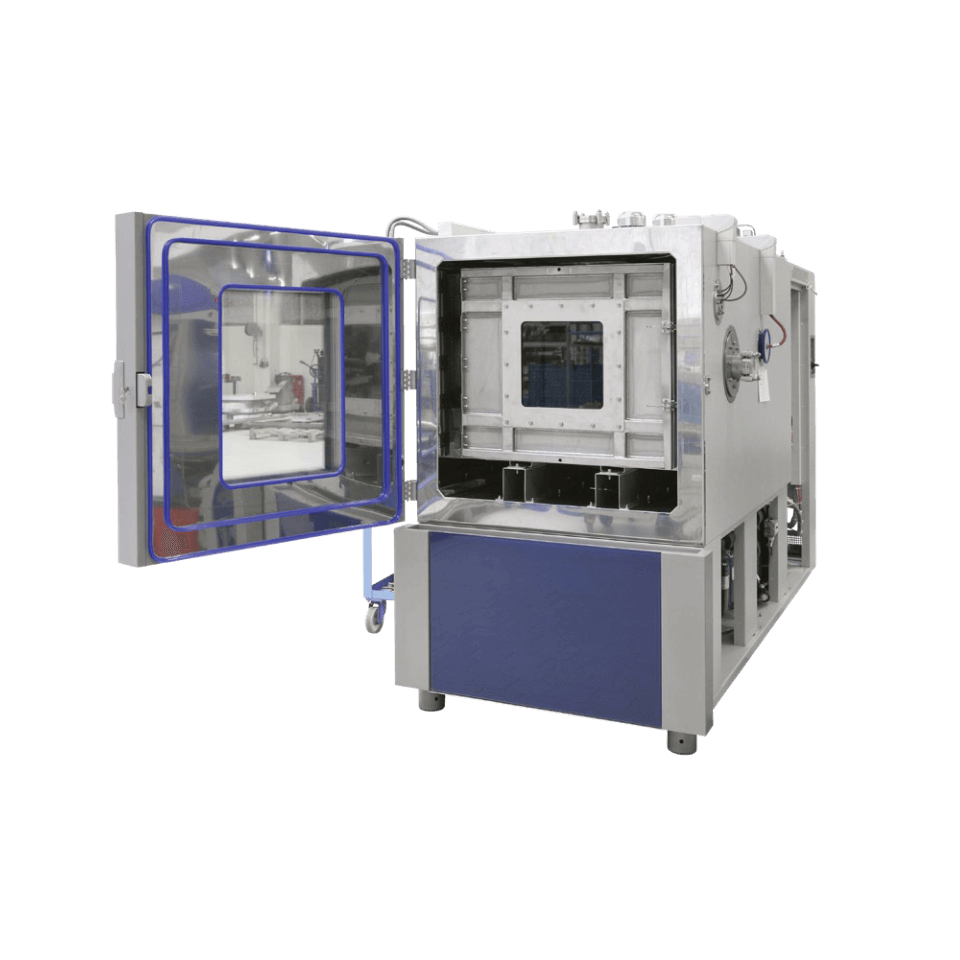

T/V and C/V series vacuum test cabinets

Altitude simulation cabinets to simulate vacuum and high altitudes

Low or reduced air pressure is an important parameter in aviation and in the automotive sector. Low air pressure in combination with extreme climatic conditions can have an impact on the safety, function and performance of a product or individual components. Vacuum or altitude simulation cabinets are therefore used to reproducibly simulate the environmental conditions for e.g. aircraft components at flight altitudes of 10,000 to 15,000 m or for vehicle components travelling in the mountains at high altitudes. The CTS vacuum test cabinets enable tests to be carried out with controlled parameters of negative pressure, temperature and humidity. Due to the special design, combined vacuum/temperature tests are possible over the entire range of pressures and temperatures.

Test space volume in litres

Rates of change

Humidity range

Temperature range

Pressure range

Standard basic equipment of the vacuum test

- Vacuum pump unit

- Vacuum container with additional air treatment installed in the basic test cabinet

- Interior lining of the vacuum container made of stainless steel

- Compressed-air supply for customer-provided compressed dehumidified air

- 1 wire mesh shelf in stainless steel, height adjustable

- 2 entry ports ø 80 mm, including a replacement false cover

- Capacitive multi-touch display in the front panel with function keys for the main system functions

- Easy-to-maintain capacitive humidity measuring system (for climatic version)

- Automatic water replenishment system (for climatic version)

- Door latch for one-handed operation, lockable

The advantages of CTS vacuum test cabinets

- Vacuum range down to 10 mbar and lower in combination with temperatures between -60°C and +120°C

- Service-friendly design

- Extremely low sound pressure level

- Temperature change rates up to 10 K/min

- Simple, user-friendly operation and programming

- Low connected load/energy consumption

- Optimised device parameters give you ultra-high precision

- Compliance with current CE and EMC regulations

- Compliance with the most common standards

CTS negative pressure chambers – main options

- Doors with observation window

- Additional vacuum entry ports

- Adaptation of the evacuation and aeration periods

- Separate Pt100 for measurement at the test specimen

- Compressed-air dryer

- Overtemperature protection for test specimen

- CID software for programming and documentation

- Further interfaces: RS232, RS485 and USB