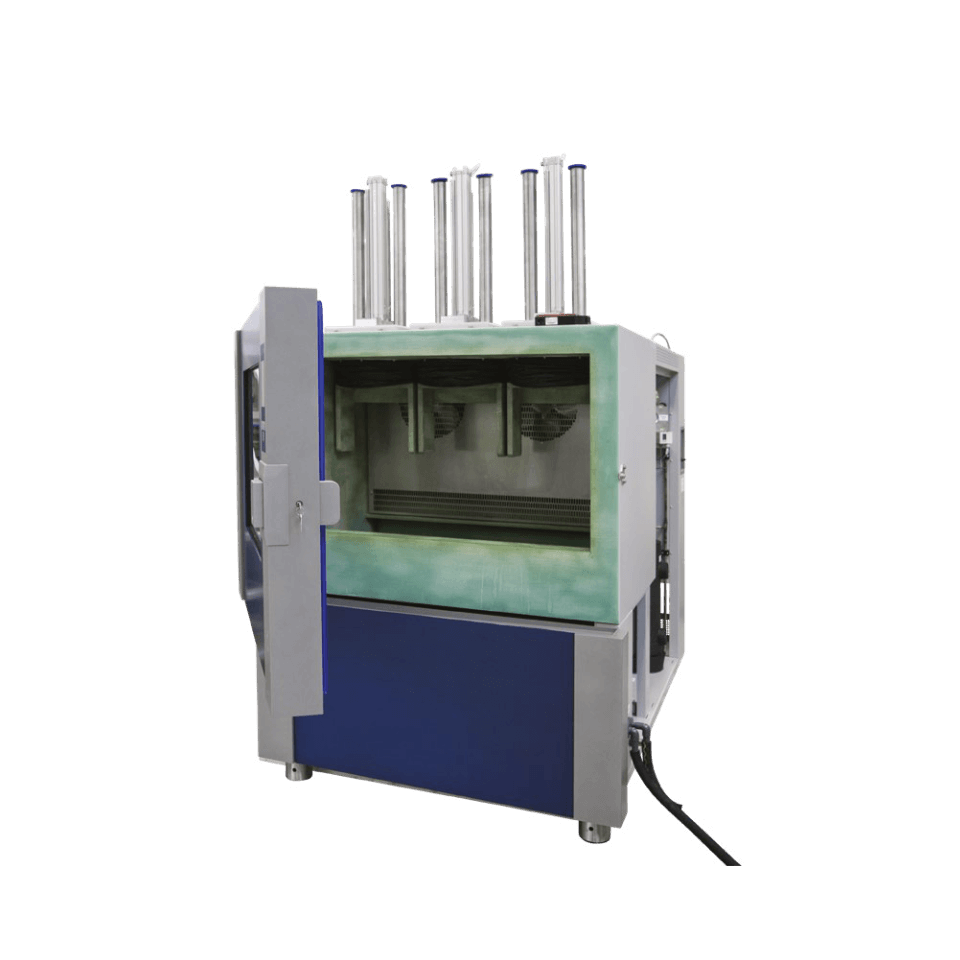

TSSL series air/liquid shock test devices

CTS environmental simulation – for reliable simulation when immersed in water

The CTS air/liquid thermal shock test units are especially designed for immersion testing in line with standards such as ISO 16750-4 or LV 124. The devices consist of 2 temperature zones: the hot chamber with air temperatures of up to +150°C and a cold zone consisting of a liquid cooling bath with water temperatures of up to 0°C. By means of the vertical hoisting mechanism, used with or without a basket, the test items are then moved from one temperature zone to the other and thus subjected to a maximum temperature shock.

This test is intended to simulate the stress on components and parts when immersed in water. The test is carried out, among other things, as a leak test after exposure to a thermal shock and thus serves to ensure that heated parts and components function in the event of immediate cooling by immersion and submersion.

Test volume in litres

Immersion medium

Salt water (5% brine)

Temperature ranges

Cold chamber: from 0 °C to +25 °C , optionally higher temperatures possible

Basic equipment of the CTS air/liquid shock test chamber

- Entire container made of glass-fibre-reinforced plastic GFRP

- 2 entry ports (50 mm) in the ceiling (moved together with the basket)

- Hot chamber up to max. +150°C

- Liquid bath with customer-provided brine, cooling down to 0°C to +25°C

- Basket made of wire mesh, material V4A

- Electromagnetic door lock

- Capacitive multi-touch display in the front panel with function keys for the main system functions

- Easy-to-maintain capacitive humidity measuring system

- USB stick connection for data storage

- Ethernet interface

- 2 digital outputs to the customer-provided test specimen controls

- Software-based min. / max. temperature limiter

CTS liquid shock test cabinets – main options

- Panoramic window 570 x 710 mm, incl. LED illumination

- Separate Pt 100 for measurement at the test specimen; can be switched over to use as control sensor

- Water-/air-cooled refrigeration unit

- Overtemperature protection for test specimen

- CID software for programming and documentation

- Additional entry ports, ø 125 and 150 mm

- Increased load for basket or test item

- Temperature of the hot chamber extended to +180°C