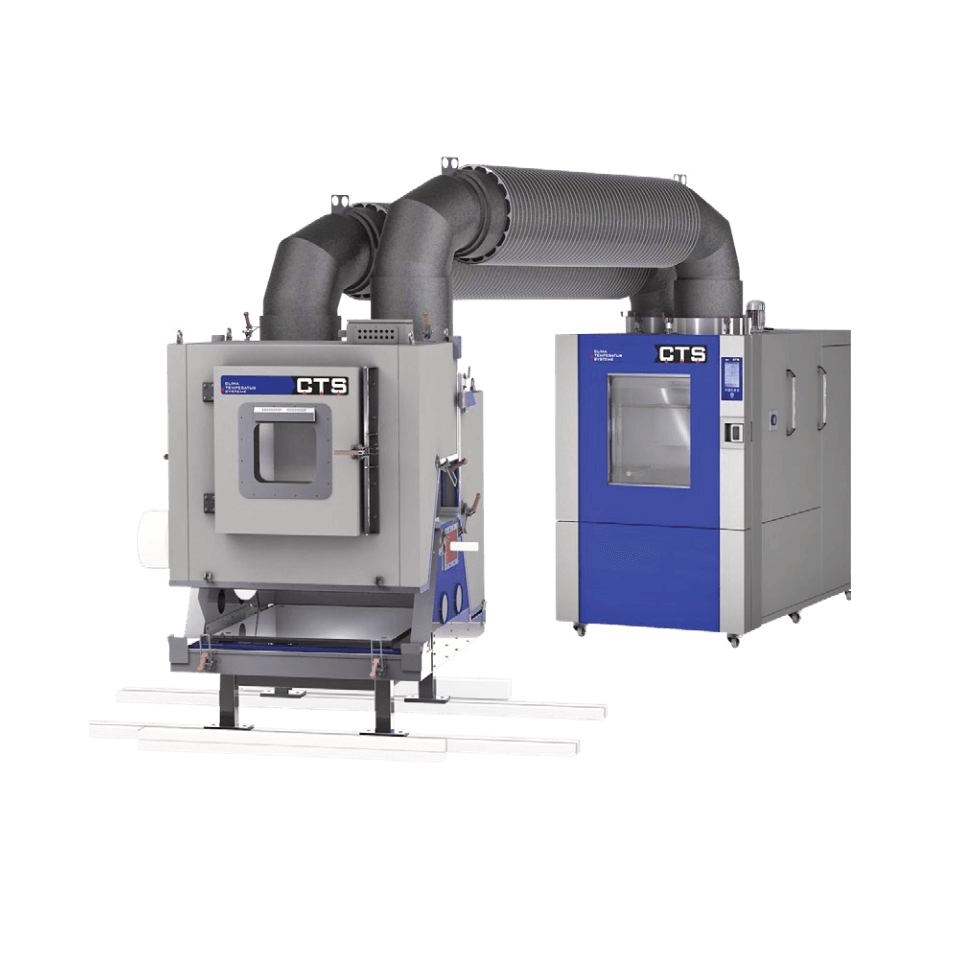

TR/CR/TSR/CSR series temperature and climatic air-conditioning devices

CTS conditioning cabinets to control the temperature of external test spaces

The CTS temperature/climatic air-conditioning devices are based on standard devices of different sizes, temperature and performance levels and can be used to control the temperature and climate of external test spaces. They are connected via special conditioning tubes.

External test spaces for user-specific uses

Systems with external test spaces are always used when the product cannot be tested in a standard cabinet for temperature or climatic testing because, for example, a connection to a test bed is necessary. The external test space can be provided by the customer or designed, manufactured and supplied by CTS specifically for the customer and the application.

A suitable device is always selected to suit the specific project and application in coordination with the customer.

Standard basic equipment of the conditioning cabinets

- Capacitive multi-touch display in the front panel with function keys for the main system functions

- Easy-to-maintain capacitive humidity measuring system (for climatic version)

- USB stick connection for data storage

- Ethernet interface

- 2 digital outputs to the customer-provided test specimen controls

- Software-based min. / max. temperature limiter

- Entry port Ø 50 mm on centre right

- Door latch for one-handed operation, lockable

- Mobile device

- Radial compressor for high recirculating rates

- Connecting pieces for the conditioning tubes

- Divider in the test space

- External PT-100 temperature sensor (control sensor), can be controlled from the box

- External capacitive humidity sensor (control sensor), can be controlled in the customer-provided box

CTS air-conditioning devices – your advantages

- Low connected load/energy consumption

- Extremely low sound pressure level

- Simple, user-friendly operation and programming

- Identical control panel in all sizes

- Dual temperature measurement by supply and exhaust air – Pt 100

- Service-friendly design

- Compliance with current CE and EMC regulations

Main options for conditioning chambers

- Panoramic window 570 x 710 mm from 200l, incl. LED illumination

- Separate Pt 100 for measurement at the test specimen; can be switched over to use as control sensor

- Compressed-air dryer

- Water-/air-cooled refrigeration unit

- Overtemperature protection for test specimen

- CID software for programming and documentation

- Speed-controlled circulation fan

- Further interfaces: RS232, RS485 and USB

- Additional entry ports, ø 50 mm, 80 mm and 125 mm

- Slot-type entry ports

- Additional use as chamber for temperature or climatic testing